Precision Roll Solutions

Experts in Engraving &

ROLL SOLUTIONS

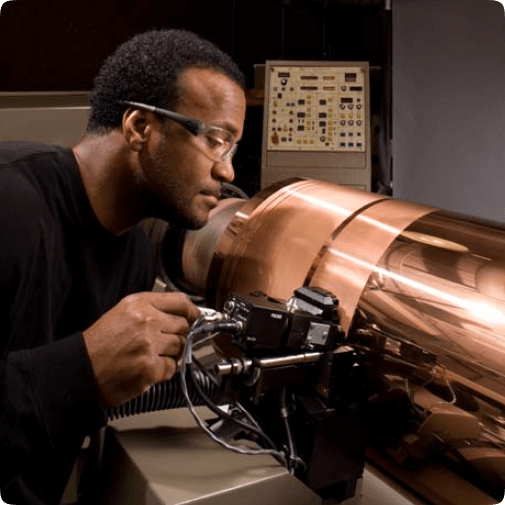

PRS strategically aligns legacy engravers under one brand to streamline the complexities of industrial embossing to deliver world-class quality across a broad range of substrates. Connect with us to learn more about the PRS advantage.

PROVEN EXPERTS.

TRUSTED PARTNERS.

Precision Roll Solutions is a partner in the truest sense of the word — committed to understanding your complex web converting roll and engraving needs, bringing our centuries of expertise to solve your challenges, and providing unparalleled service. Every aspect of our consultative experience is collaborative to provide you with seamless access to the skills, capabilities, and craftsmanship you need to achieve quality results. PRS has the experience and expertise to deliver what you need, when you need it. Period.

INDUSTRIES SERVED

PRS has proudly brought together a world-class, unparalleled collection of in-house experts who consistently deliver unmatched results with superior craftsmanship across a range of industries and applications.

AUTOMOTIVE

PRS helps automotive industry professionals stay on-trend with engraved roll solutions that create distinct competitive advantages.

CONSUMER

Leading consumer brands look to PRS for solutions engineered with quality and unparalleled craftsmanship.

PACKAGING

Challenged with a packaging substrate or print application? PRS has the experts and experience to provide practical solutions.

INDUSTRIAL

Industrial markets have unique needs and applications. PRS offers the expertise necessary to deliver top-quality, durable solutions for all types of substrates and conditions across multiple applications.

BUILDING

Building material companies seek out quality, performance, and durability in engraved rolls for their embossing needs. PRS delivers.

MEDICAL

From functionality to aesthetics, embossed substrates play essential roles in the medical industry. PRS helps you achieve safe, quality outcomes.

TECHNICAL

PRS can navigate the complexities of even the toughest technical applications.

PRODUCTS & SERVICES

When broad experience and outstanding service combine with world-class craftsmanship, you know you’re in the right place. Harness the power of PRS.

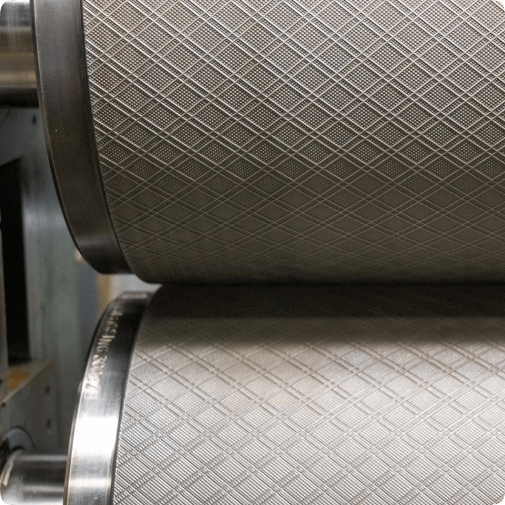

Embossing Rolls

With tried and true precision, engraved embossing rolls deliver pattern consistency, quality, and performance across a variety of substrates and applications.

Get the DetailsSpecialty Rolls

Precision-machined to exact finish and geometric tolerances, PRS specialty rolls provide versatility and optimal performance.

Get the DetailsSleeves & Print Cylinders

Optimize overall printing operations and performance with expertly crafted PRS sleeves and print cylinders.

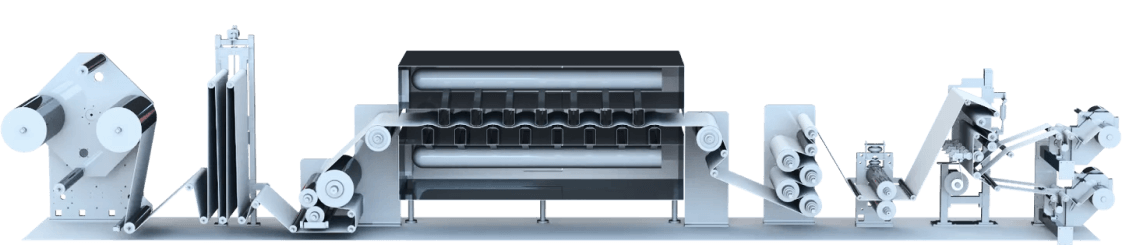

Get the DetailsMachinery

The equipment you need, when you need it — engineered to align with your specific application.

Get the DetailsServices

From pattern development and testing to roll repair and refurbishment, PRS takes a holistic approach to maximizing roll life.

Get the DetailsPRINTERS AND CONVERTERS DEPEND ON A RANGE OF PROCESS ROLLS

Process rolls for packaging are mainstays for operational quality and efficiency. PRS engineers solutions that increase throughput, reduce downtime, and maximum profitability for printers and converters.

PROACTIVE MAINTENANCE IS THE KEY TO KEEPING EMBOSSED PATTERNS FRESH

Protect your investment! Learn how proactive maintenance performed by PRS experts can help extend the depth, life, and pattern quality of engraved roll sets for aluminum and steel building products.

SUBSCRIBE TO THE PRECISION ROLL SOLUTIONS BLOG

Don’t miss out! Get news and insights from experienced, passionate PRS roll specialists.