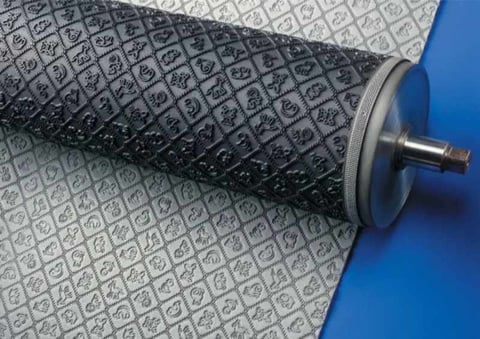

Pattern Development

VIEW DETAILS

At PRS, we have the industry’s leading pattern library, offering our customers over 100,000 standard designs. Many of these patterns have been hand cut by our leading craftsmen and not easily replicated by other engraving methods. Customers are always welcome to visit our design centers to develop new generation of patterns.

DESIGN OPTIONS

- Matching or modifying existing patterns

- New pattern development

- High-resolution scanning and digital pattern creation

- Rapid prototypes of sample textures

Using stock patterns from one of the world’s largest libraries of textures or a custom concept, PRS experts develop engraving designs to exacting specs.

Connect with

PRS Experts

Questions? Tough challenge? Need a second opinion? The PRS experts are here to guide you to your next-level engraved or precision roll solution. Set up a consultation today!