Slitters & Rewinders

VIEW SPECIFICATIONS

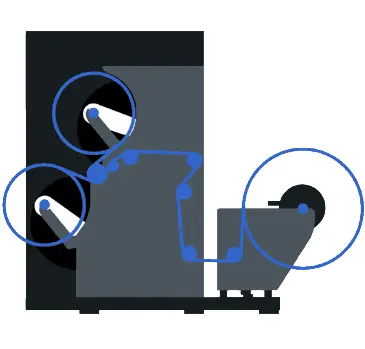

CENTER-SURFACE WINDING

Rewind Rolls are driven from the core, as well as the surface

- Because of this, the tension range on center-surface winders is the greatest possible available.

Slitting is as near the rewind point as possible

- Allowing for thin slits with excellent edge quality.

Machines can run as a center winder, surface winder, or both

- This allows a large variety in the materials that can be ran.

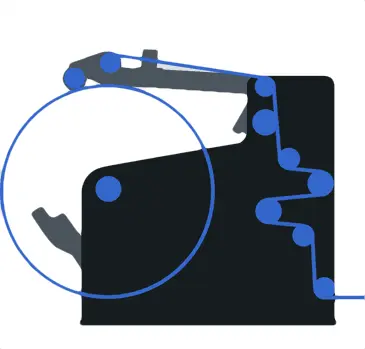

CENTER WINDING

Rewind rolls are driven from the core only

- With a single motor, the maximum diameter is limited, but the overall cost of the machine is less than a center-surface winder.

Often paired with differential shafts

- These shafts transmit torque evenly, despite diameter, so materials with gauge bands are able to be ran.

Best for high speed film processing

- Due to the rider roll, air entrapment is minimized, allowing thin extruded films to be run much faster than possible on other machines.

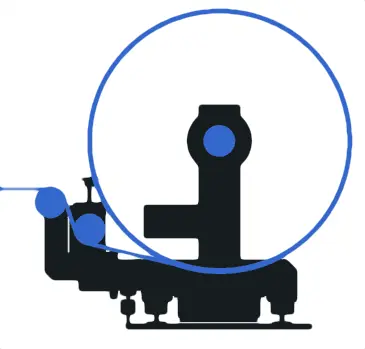

UNWINDS

Various Options for Unwind Control

- Models can be configured with single brakes, dual brakes, or motors.

Integrated Tension Control

- Load cells or dancers provide feedback to the tension control loop, allowing the stand to be integrated easily into existing production lines.

Unwind or Rewind

- Stands, including turreted stands, can be manufactured for use as an unwind stand, or as a rewind stand.

CENTER-SURFACE WINDING:

-

3050 - Center-surface slitters

-

3250 - General purpose slitter / rewinder

-

3350 - General purpose workhorse

-

3750 - For the BIG jobs

-

3850 - Heavy-duty slitter / rewinder

CENTER WINDING:

-

950 - Advanced Simplex Slitter

-

1250 - Narrow slits for film & foil

-

1750 - Wide web

-

1750T - Wide web turret

UNWINDS:

-

4510 - Shafted pedestal

-

4515 - Shaftless pedestal

-

4520 - Shafted floor pick-up

-

4525 - Shaftless floor pick-up

-

4530 - Adjustable shaftless floor pick-up

-

4790T - Turrent unwind

Center-Surface Winding

Center Winding

Unwinds

Connect with

PRS Experts

Questions? Tough challenge? Need a second opinion? The PRS experts are here to guide you to your next-level engraved or precision roll solution. Set up a consultation today!