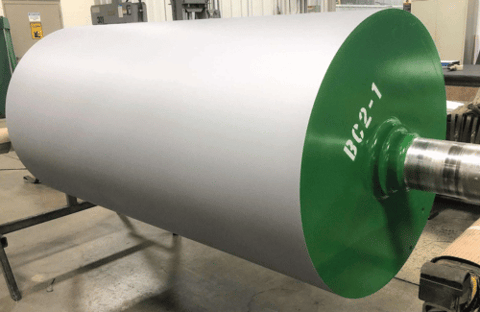

Heat Transfer Rolls

VIEW SPECIFICATIONS

.webp?width=160&height=120&name=DSC_8166%20(2).webp)

Precision-engineered temperature control for converting and web handling systems

Precision Roll Solutions manufactures custom heat transfer rollers designed to maintain stable surface temperatures across high-speed production processes. Whether used for chilling, heating, or thermal conditioning, PRS rolls deliver uniform thermal performance.

Applications

Film extrusion – chill rollers for post-extrusion stability

Lamination and coating – thermal control before or after material application

Paper converting – curl and moisture management

Nonwovens – consistent bonding through controlled heating or cooling

Industrial coating – substrate prep for adhesives or chemical layers

PRS offers a full range of heat transfer roller configurations tailored to your system:

- Single Wall Design – Basic construction for light-duty applications

- Double Wall Design – Spiral baffles enhance thermal contact and flow control

- Mono-Flow – Inlet/outlet on opposite ends, ideal for large systems

- Duo-Flow – Inlet/outlet on the same end for compact setups

- Spiral (Non-Contact) – Eliminates dead zones and ensures uniform temperature

- Full-Contact Fit – Maximum rigidity and stability in demanding applications

- Manufactured to print or engineered custom to the end-user’s application

- Precision-machined to meet finish and geometric tolerances

- Engineered for guaranteed thermal and physical performance

- Temperature control tolerance across the roll face (+/-1°F)

Connect with

PRS Experts

Questions? Tough challenge? Need a second opinion? The PRS experts are here to guide you to your next-level engraved or precision roll solution. Set up a consultation today!