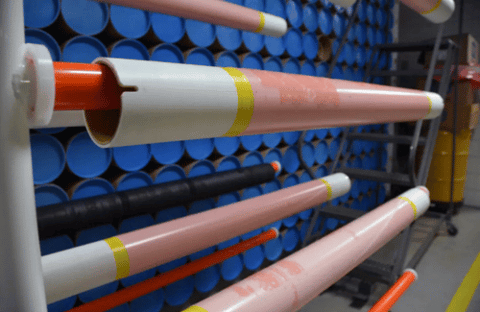

Flexo Plate Mounting Sleeves

VIEW SPECIFICATIONS

Flexo Plate Mounting Sleeves

Engineered for Durability. Built for Precision.

Precision Roll Solutions’ flexo sleeves are built to perform under pressure—day in and day out. Designed to endure heat, wear, and harsh chemicals, our sleeves maintain tight tolerances even in the most demanding printing environments.

Whether you're running water-based, UV, or solvent inks, PRS flexo sleeves deliver consistent, long-term performance for printers who can't afford downtime.

-

Brass-reinforced notches, scribe lines, and protective end plates for increased durability

-

Sleeve ID label includes specs and custom info per your request

-

Resurfacing options available for used sleeves to extend product life

-

Most sleeves available up to 80" in length

-

Custom applications available up to 120"

-

Diameters from 2.295" to 14.869" (larger sizes available upon request)

-

Compatible with sticky-back tapes; resistant to solvent, water, and UV-based inks

-

Precision tolerances: TIR ≤ .0005", Diameter tolerance ≤ .0005"

-

Designed for high-volume flexographic printing environments

-

Proven durability in label, flexible packaging, corrugated, and envelope production

-

Ideal for converters seeking repeatable performance and longer sleeve life

Trusted by converters and OEMs across North America, PRS flexo sleeves deliver the reliability, precision, and durability today's pressrooms demand.

Connect with

PRS Experts

Questions? Tough challenge? Need a second opinion? The PRS experts are here to guide you to your next-level engraved or precision roll solution. Set up a consultation today!