PRS Products & Services

Precision Rolls, Sleeves & Converting Equipment—Engineered for Performance.

What We Do

PRS designs and manufactures custom-engineered industrial rollers, sleeves, and web converting equipment that solve real production challenges. Whether you’re printing, embossing, coating, laminating, or rewinding, we help you hit tighter specs, reduce downtime, and get to market faster.

Our solutions are built to:

-

Transfer inks and coatings with precision

-

Apply adhesives with accuracy

-

Control web tension, heat, and registration

-

Replicate consistent textures and functional surfaces

-

Improve uptime, repeatability, and changeover speed

We support converters and OEMs across packaging, tissue, nonwovens, films, automotive, and industrial applications, with everything from prototyping to lifecycle support.

HOW WE WORK:

OUR 4-STEP DEVELOPMENT PROCESS

1. Discover

We start by understanding your line conditions, production goals, and technical challenges.

2. Design & Develop

Our engineering and applications teams collaborate with you to create custom roll geometry, patterns, or full machine systems.

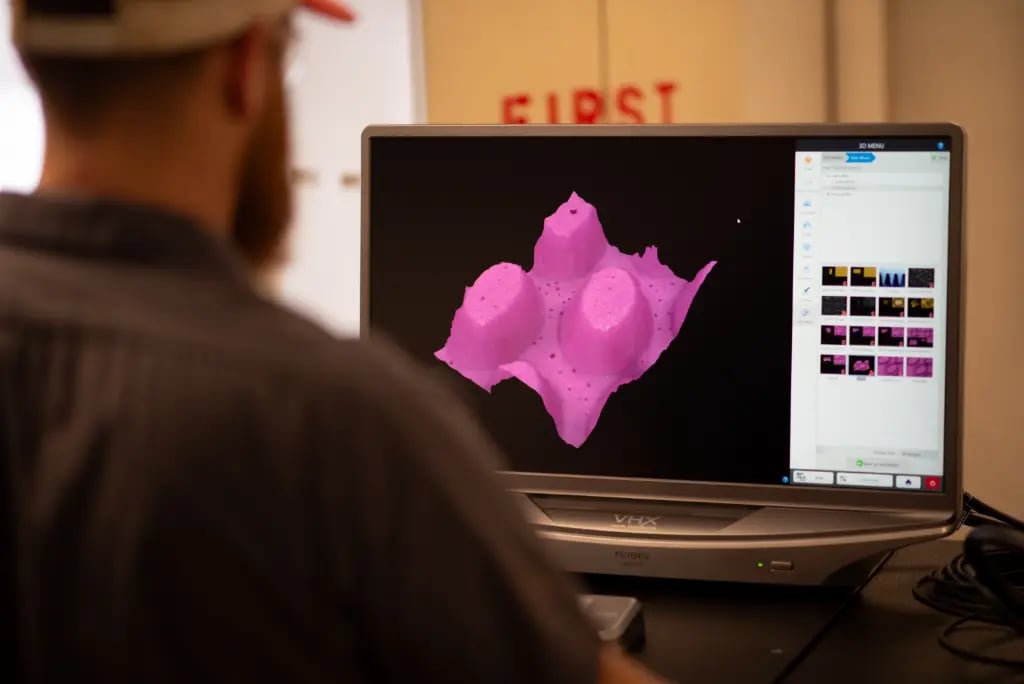

3. Prototype & Test

Our in-house pilot lines and pattern testing labs validate performance before full-scale production.

4. Manufacture & Support

Your rolls and machines are built in the U.S. and backed by support that includes audits, spare parts, refurbishing, training, and field service.

.

We don’t just supply components—we solve web handling & converting challenges

From flexible packaging and tissue to nonwovens and films, PRS delivers purpose-built solutions for converters, OEMs, and industrial manufacturers across North America.

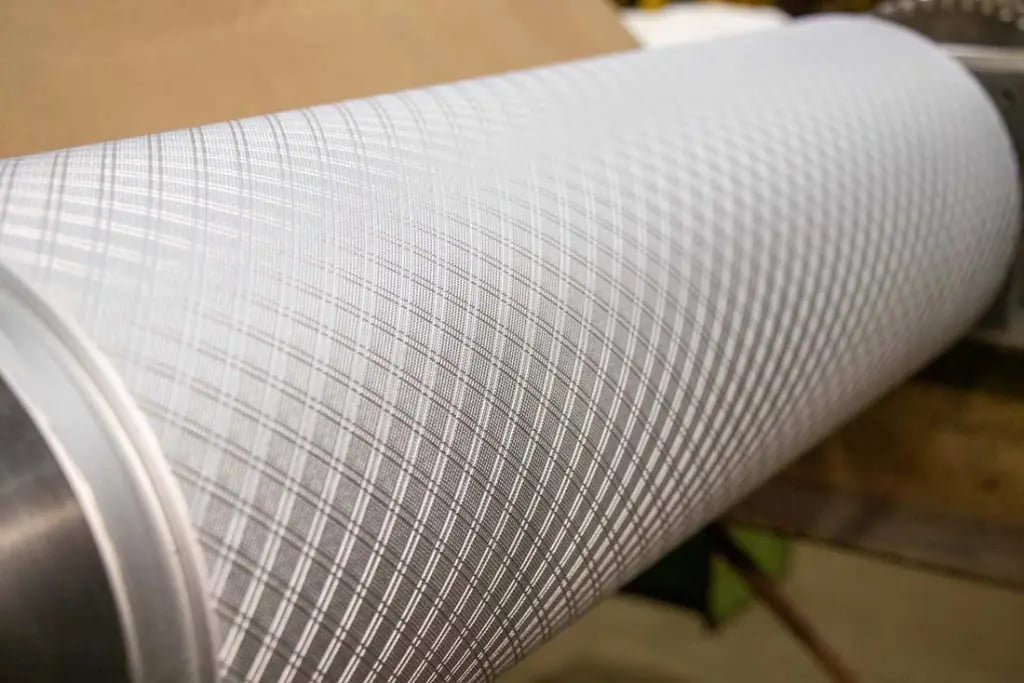

Engraved Rolls

Engraved embossing rolls, calendering rolls, glue/meter rolls, and gravure print cylinders that deliver pattern consistency, quality, and performance across a variety of substrates and applications.

Get the Details

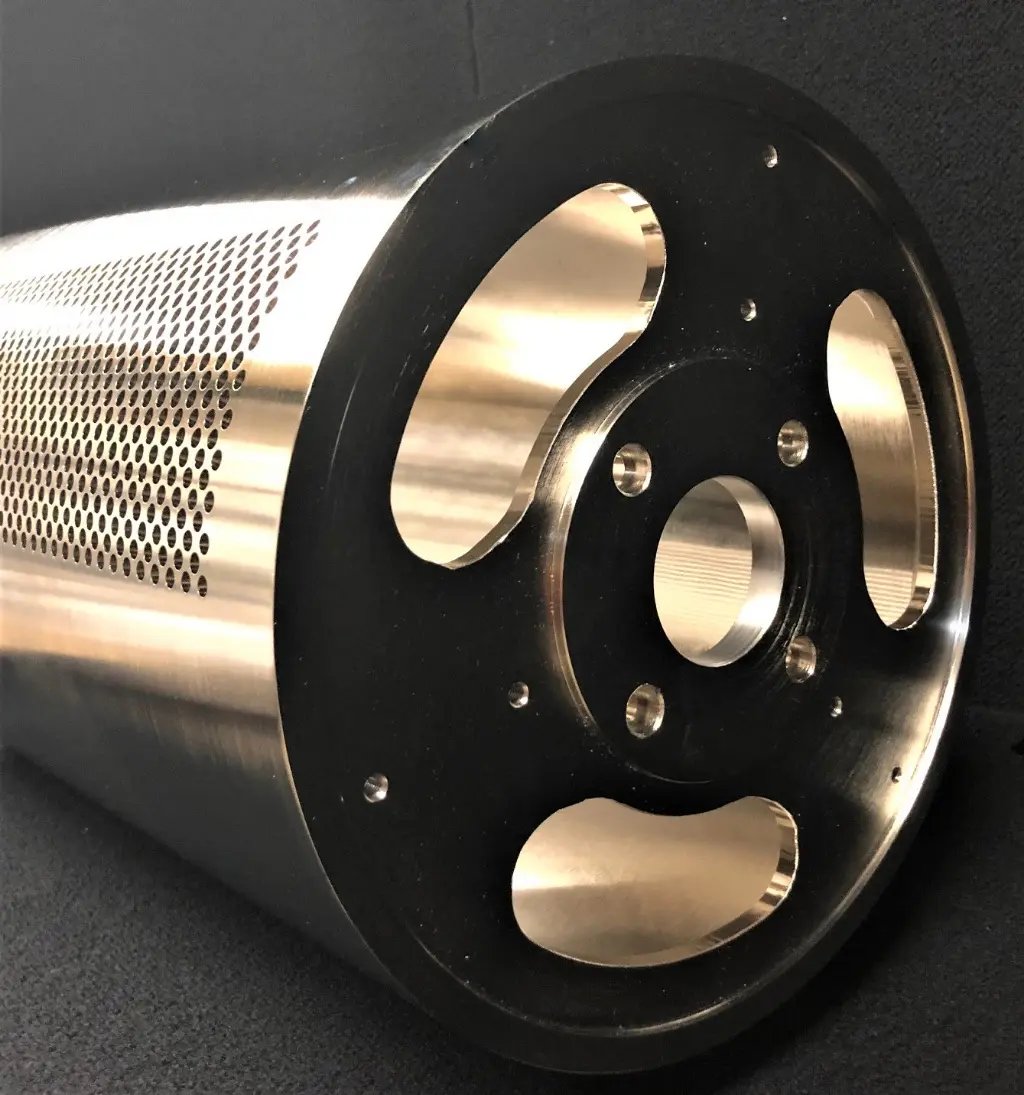

Specialty Rolls

Precision-machined to exact finish and geometric tolerances, PRS specialty / web handling rolls (vacuum tension rolls, heat transfer rolls, custom rolls) provide versatility and optimal performance.

Get the Details

Print Sleeves and Components

Optimize printing operations and performance with expertly crafted PRS print sleeves (flexographic sleeves, anilox sleeves, bridge sleeves), anilox bases and roll covers.

Get the Details

Machinery

The equipment you need, when you need it — engineered to align with your specific application.

Winders, unwinds, slitters, embossers, calenders, and custom web converting equipment.

Get the Details

Services

From product pattern development, pilot testing, roll re-engraves and refurbishment, audits and technical support, PRS takes a holistic approach to helping bring your idea to life.

Get the Details

Connect with

PRS Experts

Questions? Tough challenge? Need a second opinion? The PRS experts are here to guide you to your next-level engraved or precision roll solution. Set up a consultation today!