Industrial Embossing Rolls

VIEW SPECIFICATIONS

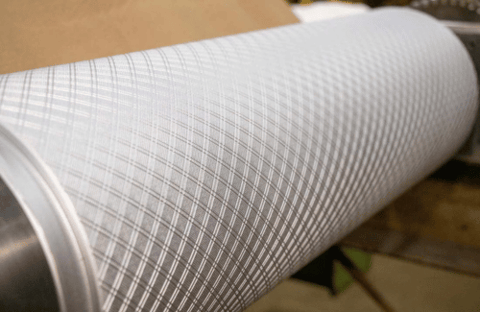

Embossing Rolls

High-Speed Converting. High-Precision Embossing.

PRS embossing rollers are engineered to enhance material function, surface appearance, and product differentiation across a wide range of converting and industrial applications.

Whether you're embossing tissue, towel, nonwovens, films, liners, or metals, our rolls deliver consistent pattern transfer, at production speeds. We offer mechanical, chemical, and laser engraving for embossing rollers, custom to your substrate and performance needs.

Common embossing roller applications include:

-

Tissue & Towel – Patterns that build bulk and absorbency to napkins, bath tissue, and dispensers

-

Nonwovens – Facilitates bonding and strength for hygiene, medical, or filtration uses

-

Bag & Can Liners – Improves stretch and puncture resistance

-

Technical Films & Extruded Substrates – Optimizes surfaces for lamination, adhesion, or clarity

-

Building Materials – Replicates woodgrain and decorative patterns for flooring and siding

-

Automotive – Enhances tactile or aesthetic finishes for interior films and molded components

-

Metals & Industrial – Delivers functional or decorative textures on steel, foil, and heavy-duty materials

-

Max Weight Capacity: Up to 11 tons

-

Max Overall Length (OAL): Up to 372"

-

Max Diameter: Up to 36"

-

Pattern Prototyping: Rubber-to-steel and matched steel up to 12" wide

-

Surface Treatments: Chrome, nickel, copper, or custom finishes

-

Engraving Types: Mechanical, chemical, or laser engraving

-

Custom Geometry: Sidewall angle, radiusing, and depth customization available

-

Sizes: Custom roll sizes available—contact us to discuss your application

-

Full roll refurbishment for PRS and customer-supplied rolls

-

Journal repair and precision balancing

-

Re-engraving with updated or existing patterns

-

Removal of legacy engraving and surface preparation

-

Inspection and evaluation to extend roll life

-

Supports high-speed converting across tissue, film, foil, nonwovens, and extruded materials

-

Delivers consistent embossing depth and high-fidelity pattern transfer

-

Optimized for lamination, bonding, absorbency, texture, and visual appeal

-

Designed for use with mechanical, chemical, or laser-engraved patterns

-

Compatible with OEM and legacy embosser systems

-

Customizable for tactile performance, aesthetic enhancement, or structural function

PRS leverages cross-industry insights to develop embossing rolls that outperform expectations. Our experience across materials and markets gives you an unmatched advantage in pattern development and roll design.

Connect with

PRS Experts

Questions? Tough challenge? Need a second opinion? The PRS experts are here to guide you to your next-level engraved or precision roll solution. Set up a consultation today!