Vacuum Tension Rolls (VTR)

VIEW SPECIFICATIONS

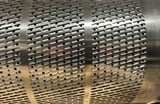

Vacuum Rolls or also known as Vacuum-Tension Rolls (VTR) or Vacuum Pull Rolls (VPR), are hollow rollers with perforated outer shells through which a vacuum is drawn. A sealed center tube creates a confined vacuum zone; the resulting pressure differential and surface friction allow you to precisely hold back or pull the web to control tension. Drive pulleys or journals on the outer shell then adjust or isolate tension as needed. Built for rugged, long-life performance, PRS Vacuum Rolls give web coaters and converters exact tension control for optimal throughput and quality.

-

Screen Options: Protect delicate webs—fine-mesh screens minimize marking, while seamless screens eliminate any seam-induced defects.

-

Width Adjustment:

-

Mechanical—infinitely adjustable; visual indicator shows the exact setting.

-

Pneumatic—automation-friendly; tighter seal clearances for more efficient vacuum.

-

-

Surface Treatments:

-

Electroless Nickel Plating—smooth, corrosion-resistant finish

-

Rubber Covering—compliant surface for maximum traction

-

Plasma Coating—high-release, enhanced grip

-

Fine-Mesh Screens—non-marking, ideal for thin or sensitive materials

-

Mechanical Micro-Groove Engraving—improved traction and exhaust efficiency

-

-

Standard Diameters: 175 mm (6.890″) to 450 mm (17.717″)

-

Custom Sizes & Finishes: Available on request to fit any web width or line speed

-

Vacuum Zone Control: Single-side contact eliminates boundary-layer slip for consistent tension

-

Materials & Construction: Carbon or stainless-steel cores, precision-machined shells, and dynamic balancing for vibration-free operation

Connect with

PRS Experts

Questions? Tough challenge? Need a second opinion? The PRS experts are here to guide you to your next-level engraved or precision roll solution. Set up a consultation today!